In biotechnology or similar fields, you're bound to encounter various lab filtration apparatuses in your work or studies. Whether you're looking to understand this process for professional reasons or considering setting up a home lab, this article will guide you through the essentials of laboratory filtration. Here’s what we’ll cover:

- Understanding Laboratory Filtration: A brief introduction to what lab filtration is and its significance in scientific research and industrial applications.

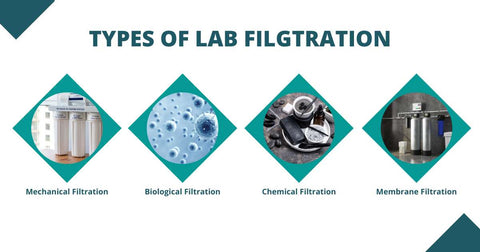

- Types of Lab Filtration: An overview of the main types, including:

- Mechanical Filtration

- Biological Filtration

- Chemical Filtration

- Membrane Filtration

- Applications: We’ll explore how this process is applied in different sectors, highlighting its versatility and importance in:

- Purification and Sterilisation

- Environmental Monitoring

- Pharmaceuticals and Biotechnology

- The Food and Beverage Industry

- The Importance of Lab Filtration: An insight into why it is crucial for quality control, safety, efficiency, cost-effectiveness, and environmental protection.

- Setting Up for your own Filtration System: Essential considerations and equipment needed if you want to perform laboratory filtration in a home lab setting, including:

- Choosing the Right Filtration Apparatus

- Understanding Filtration Media

- Safety Measures and Best Practices

Understanding Lab Filtration

Lab filtration is an important process used to separate solids from liquids. This process involves passing a mixture through a filter that catches the solid particles while allowing the liquid to flow through. The filter used varies depending on the size and type of particles being separated.

This process is commonly used in various industries, including food and beverage, environmental testing, and pharmaceuticals to remove impurities, purify liquids, and collect solid samples for further analysis.

The Different Types of Laboratory Filtration

The most prevalent types include:

Mechanical Filtration:

This method involves passing a fluid through a filter medium that physically traps solids and allows only the purified liquid or air to pass through. The filter media used can vary widely depending on the size of the particles to be removed. This technique is essential in settings where clarity of liquids is paramount, such as in water treatment facilities, as well as in air purification systems where particulate matter needs to be filtered out.

Biological Filtration

This method employs living organisms, such as bacteria, to metabolise and remove contaminants from water, air, or soil. This process is particularly beneficial in maintaining a balanced ecosystem in aquaculture, wastewater treatment, and aquarium maintenance. The process helps not only in detoxifying the environment but also contributes to the natural cycle of nutrient conversion.

Chemical Filtration:

This advanced form of filtration selectively removes specific chemical substances from a mixture through chemical reactions using reactive materials such as activated carbon, ion exchange resins, and other adsorbents. This technique is critical in scenarios where the purity of chemical compounds is essential, such as in the pharmaceutical industry, and in the scrubbing of industrial emissions to prevent harmful substances from being released into the atmosphere.

Membrane Filtration:

This method employs a semipermeable membrane to separate particles based on size, molecular weight, or specific interactions with the membrane surface. This category encompasses a range of techniques, including:

- Microfiltration (MF): Targets the separation of larger particles and bacteria from liquids.

- Ultrafiltration (UF): Used to concentrate and purify proteins and remove viruses.

- Nanofiltration (NF): Effective in softening water and removing specific organic compounds.

- Reverse Osmosis (RO): Offers the finest level of filtration, removing ions and small molecules from solutions, making it essential for desalination and the production of ultrapure water.

Applications in Different Industries:

- Purification and Sterilisation: At its core, lab filtration excels in the purification of chemical reagents and sterilising biological samples. Imagine preparing a petri dish for growing bacteria or ensuring a chemical reaction isn't tainted by impurities—filtration is your go-to. It's the unsung hero in microbiology and molecular biology labs, where the clarity and purity of media can make or break an experiment.

- Environmental Monitoring: Picture the role of a detective, but instead of solving crimes, this process helps pinpoint environmental contaminants in air and water samples. This is critical for monitoring pollution levels, and ensuring that regulatory standards and public health are upheld. It's a tool for both protection and prevention, serving as a guardian of our natural surroundings.

- Pharmaceuticals and Biotechnology: In the realm of drug development and vaccine production, filtration is akin to a gatekeeper, ensuring that only the safest and purest products make it to market. It's about removing the unseen—particulates and microorganisms—that could compromise safety. For professionals in these fields, filtration is not just a step in the process; it's a pledge of safety and efficacy to consumers.

- Food and Beverage Industry: Here, laboratory filtration contributes to the clarity of beverages and the safety of food items, ensuring that the only thing consumers taste is quality. Whether brewing beer, processing dairy, or ensuring water purity, filtration safeguards flavours and against contaminants.

Why Lab Filtration is Important

The significance of this process is multifaceted, blending the practical with the essential:

- Quality Control: Imagine crafting a masterpiece, only to have a smudge ruin it. In scientific and industrial processes, filtration ensures that such "smudges" are removed, leading to outcomes that are as intended—pure, accurate, and reliable. It's about maintaining standards and ensuring that the final product reflects precision and care.

- Safety: Filtration acts as a barrier against the microscopic dangers that could compromise health, from bacteria in pharmaceuticals to contaminants in drinking water. It's a shield that protects both the professionals in the lab and the end consumers, contributing to safer products and working environments.

- Efficiency and Cost-Effectiveness: In the balancing act of production and conservation, filtration emerges as a method that saves time and resources. It's an elegant solution that often requires less energy and fewer materials than its alternatives, making it a smart choice for businesses looking to optimise their operations without sacrificing quality.

- Environmental Protection: Beyond the confines of labs and factories, filtration plays a crucial role in the broader context of environmental stewardship. By monitoring and mitigating pollution, filtration systems help preserve our ecosystems, ensuring that the planet remains a viable home for future generations.

Get Started and Build a Robust Filtration System

Discover the excellence in filtration with our top-tier Filtration Assemblies and Equipment. Tailored for industries like pharmaceuticals, food and beverage, and environmental monitoring, our products promise unmatched purity, safety, and efficiency.

Embrace state-of-the-art membrane filters, mechanical, and chemical filtration systems designed to elevate your operations. Ensure superior quality and performance with our advanced solutions.

Check Out Our No-Frills Filtration Kit

Are you setting up a home lab or conducting experiments in your educational institution? Look no further! Our Vacuum Filtration Kit combines functionality, convenience, and affordability to meet your filtration needs.

Key Features:

- Create a vacuum effortlessly with our manual pump.

- Ideal for separating solids from liquids quickly and efficiently.

- Available in various capacities (100ml, 250ml, 500ml, 1000ml, 2000ml, 5000ml).

- Crafted from high-quality glass for durability.

- Designed for seamless filtration processes.

- Sized perfectly to fit the funnel.

- Ensures precise filtration results.

- Say goodbye to messy spills!

- Secures the funnel to the flask.

- Provides a leak-proof seal.

- Easy to use and maintain.