A heating mantle is a specialised device that provides a safer alternative to open flames or Bunsen burners when dealing with flammable liquids in a laboratory. The device envelops laboratory glassware in a gentle and controlled embrace of heat, ensuring uniform heat distribution around the flask or container. This feature is especially important for sensitive reactions where even minor temperature fluctuations can alter the outcome.

They’re Flameless and Protects Against Bursting Liquids

Picture this: You’re conducting an experiment involving organic solvents, and precision is crucial. The last thing you want is an accidental fire erupting in your lab. This heating apparatus has a protective barrier between the heating element (usually a coiled wire) and the container. Having this separation significantly reduces the chances of mishaps.

When dealing with volatile organic liquids that have a tendency to burst when exposed to direct heat, this lab apparatus becomes more than just a convenience—it’s a crucial safety measure.

Provides Precise Temperature Control

Chemical reactions and processes thrive on consistency. If you need to synthesise compounds, perform extractions, or conduct refluxing experiments, you need to maintain a constant temperature. Having this apparatus allows you to fine-tune the heat precisely so you don’t make any errors or variances in your experiments.

Here’s how it works: Connecting the mantle to a Variac (a variable transformer) gives you control over the voltage supplied to the heating element. Adjusting the Variac dial lets you fine-tune the temperature as needed.

A Variac set to “100” corresponds to full power, while a setting of “50” halves the delivered voltage. This level of control ensures that your reactions proceed smoothly and predictably.

Also A Versatile Laboratory Tool

They are versatile workhorses in the lab. They find applications in various processes, including:

- Evaporation: When you need to remove solvents or concentrate solutions gently.

- Distillation: For separating components based on their boiling points.

- Extraction: Imagine extracting precious compounds from complex mixtures—this apparatus makes it possible.

- Refluxing: Maintaining a constant boiling temperature during chemical reactions.

Efficient and Even Heating

The design of laboratory equipment is no accident. Their cup-shaped form ensures uniform heat distribution around the flask, or any heat-resistant container for that matter. This feature is especially beneficial for sensitive reactions where even minor temperature fluctuations can alter the outcome. Whether you’re crystallising compounds or conducting enzymatic assays, the even heat distribution matters.

Can Reach Higher Temperatures

Compared to other heating devices, this apparatus can crank up the heat. Need to reach elevated temperatures for specific applications? No problem. From organic synthesis to polymerisation, these mantles can handle it. Just remember to adjust the Variac accordingly and proceed with caution.

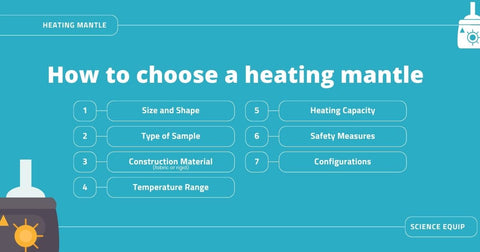

How to Choose a Heating Mantle

Selecting the right heating mantle for your laboratory or experimental setup involves considering several crucial factors. Let’s explore these considerations to help you make an informed choice:

Size and Shape

Ensure it fits snugly around your glass container (such as a flask or beaker). This tool comes in various sizes and shapes, so choose one that best suits your experiment’s vessel dimensions.

Type of Sample

Identify the type of sample you’ll be working with (e.g., organic liquids, solvents, or mixtures).

This essential tool is particularly useful when dealing with organic liquids that can burst into flames when exposed to direct heat. Consider the flammability and reactivity of your sample when selecting a mantle.

Construction Material

- Fabric Mantles: These are flexible and can mould to accommodate various flask shapes and sizes. They are generally cheaper but susceptible to damage from spilled liquids.

- Rigid Mantles: These have specific receptacles shaped for particular flask sizes or sand-filled orifices for holding various flasks. Rigid mantles provide more uniform heating but are pricier.

Temperature Range

Check the temperature range offered when you’re shopping around. Ensure compatibility with your experimental requirements, especially if you need to work at extreme temperatures.

Heating Capacity

Determine the required heating capacity based on the volume and nature of your samples or vessels. Also, consider the maximum temperature you’ll need to achieve and select a mantle that can handle it efficiently.

Safety Measures

Anything that generates high heat draws intense energy, so never plug them directly into a wall socket. Use a transformer (such as a Variac) or an electronic relay/switch between the mantle and the wall socket to prevent blowing fuses or melting the wiring.

Configurations

They also come in different configurations:

- Mantle and Controller Unit: Combines the mantle and its temperature controller.

- Mantle Only: Just the container for holding the flask, without a temperature controller.

- Controller Only: The instrumentation board for controlling the heating, not the mantle itself.

Remember, precision and safety go hand in hand. Make sure to choose one that aligns with your lab needs and is high-quality.

How to Choose a Flask for Your Heating Mantle

Not every glassware can be used on a heating mantle. In fact, there are only certain types of flasks that are compatible with it. Here are some guidelines to help you choose the right one:

- Round Bottom Flasks: If you primarily work with round bottom flasks, round or hemispherical heating mantles are your best bet. These mantles are specifically designed to fit round-bottomed glassware. They provide uniform heating and are ideal for organic chemistry, distillation, and pharmaceutical applications.

- Spherical Flasks: Spherical flasks should be placed inside the heating mantle and filled with liquid. Be cautious not to put a small spherical flask in a large-diameter heating mantle, as this can lead to issues. Spherical flasks come in various volumes, ranging from 50 ml up to 20 litres. Remember that leakage or breakage of liquid from the spherical flask can damage the heating mantle.

-

Consider the Shape: Heating mantles are typically cup-shaped and designed for specific sizes of round-bottomed flasks. Due to their fixed shape, only flasks of exact volume or very close volume can be used. Keep in mind that spills can potentially damage the exposed heating element, so be careful when handling them.

Heating Mantle or Hotplate? Which One Should You Go For?

Two things come to mind when it comes to conveniently heating liquids or chemicals inside glassware. There’s the heating mantle that we have discussed so far, and then there’s the hotplate. Both serve the same purpose, but to help you make an informed decision, consider the following factors:

Heating Mantle

- Heat Source: Heating mantles use electrical resistance heating and are commonly used to heat solutions in round-bottomed flasks. They typically operate at lower temperatures (around 100 to 250 degrees Celsius), making them suitable for heating solvents, oils, and other volatile liquids that might evaporate or decompose at high temperatures.

- Uniform Heating: Heating mantles provide a more uniform heating distribution because the heating element is wrapped around the container, ensuring consistent heat throughout the flask.

- Insulation: The fabric or metal mantle of a heating mantle acts as insulation, reducing the need for frequent adjustments or calibration.

- Safety: Heating mantles are preferred when handling flammable solutions due to their enclosed heating system insulating the heating element from the sample vessel.

Hot Plate

- Heat Source: Hot plates are heated metal plates that can be used for heating a variety of containers, including beakers, flasks, and evaporating dishes. They are also suitable for heating solids.

- Uneven Heating: Hot plates heat the container directly through contact with the heated plate, resulting in uneven heating.

- Capacity: Hot plates can handle larger volumes than heating mantles. While heating, mantles typically handle around a litre, depending on your round bottom flask. Meanwhile, hotplate stirrers can handle heat up to 20 litres of volume.

In summary, choose a heating mantle for precise control, uniform heating, and safety when working with volatile liquids. Opt for a hot plate when heating larger quantities or batches of chemicals.

Ready To Get Started?

If you're looking for a reliable and precise heating mantle, the Science Equip: Digital Display Heating Mantle is an excellent choice. Equipped with a PID Single Screen Temperature controller, this mantle provides accurate and real-time temperature readings. It also boasts fast heating, temperature uniformity, and highly precise temperature control.

Safety is a top priority, and this comes with several features to make sure of that. This includes over-temperature protection, adjustable heat and temperature settings, and a housing made from heat-resistant materials.

To make your work even more comfortable, this mantle has a PT100 temperature sensor, an adjustable sensor rack, and stainless steel rods. With this lab equipment, you can enjoy reliable, safe heating, and precise temperature control for all your laboratory needs.

So why not consider adding it to your lab equipment? Make your time at the lab a safe and seamless one with a reliable tool to support your scientific journey.